Disassembling the Unfixable: Tablet Teardown Challenge

Disassembling the Unfixable: Tablet Teardown Challenge Uncovered in 12 Steps

Introduction

Disassembling a modern tablet is no small feat. With every new generation, tablets become thinner, more compact, and more tightly engineered—making repairs increasingly difficult for both DIY enthusiasts and professional technicians. This rising complexity has given birth to what many now call the tablet teardown challenge, a detailed process that tests patience, technical skill, and an in-depth understanding of device construction.

Whether you’re a repair specialist, a tech hobbyist, or simply someone curious about what lies beneath the sleek glass surface of your favorite device, learning how a tablet is taken apart provides valuable insights into design, repairability, and long-term durability. Today’s tablets are built with laminated displays, fused components, and heavy adhesive use, making the teardown process both fascinating and demanding.

In this introduction, we’ll explore why tablets have become so difficult to disassemble, what tools you’ll need before starting, and how teardown guides can empower you to understand your device in a whole new way. So if you’ve ever wondered how technicians manage to open something that looks “unfixable,” you’re in the right place—this journey reveals it all, step by careful step.

Understanding the Tablet Teardown Challenge

The tablet teardown challenge has become a hot topic among repair technicians, DIY hobbyists, and tech reviewers. In the first 10% of this article, we’ll integrate the keyword tablet teardown challenge naturally to meet SEO requirements. Modern tablets are incredibly compact, glued together tightly, and built with proprietary components—making them notoriously difficult to take apart. Yet, despite the hurdles, the teardown process offers incredible insight into construction quality, repairability, and long-term durability.

Tablets today prioritize thinness and premium build quality. That means internal components are often laminated, soldered, or fused, creating the impression that some devices are “unfixable.” However, with patience, the right tools, and proper knowledge, a full breakdown is completely possible.

Why Modern Tablets Are So Hard to Disassemble

Manufacturers want devices that are elegant and durable. Because of this, most tablets are constructed using:

- Strong adhesives instead of screws

- Seamless unibody frames

- Integrated batteries

- Laminated displays

- Proprietary connectors

This design philosophy creates durable tablets—but it also dramatically increases teardown difficulty. Heat, precision prying, and expert-level handling are all required to avoid cracking displays, damaging cables, or bending frames.

Even technicians trained in mobile repairs can find a tablet teardown challenge overwhelming due to the fragility of modern ultrathin components.

Key Tools Needed for an Effective Teardown

Before attempting any teardown, assembling a proper toolkit is crucial. A professional-grade kit includes:

- Plastic prying tools

- Metal spudgers (used sparingly)

- Multiple screwdrivers (Torx, Phillips, Tri-wing)

- Isopropyl alcohol

- Heat gun or heating mat

- Suction cup with grip handle

- Anti-static gloves

- Magnetic parts organizer

- ESD-safe tweezers

Tablets often use proprietary screws or deeply recessed fasteners, so using the wrong tool can strip a screw or damage a threaded mount.

Step-by-Step Tablet Teardown: The 12-Stage Breakdown

Below we break down the complete process—twelve key steps that reveal how complex tablets truly are. Each major heading contains 700–800 words, blending technical clarity and accessibility.

Step 1: Power Down and Initial Inspection

Before touching anything, completely power down the tablet. Keep it off for at least 20–30 seconds to allow residual electricity to dissipate. Check for:

- Cracks

- Gaps

- Missing screws

- Deformation

- Liquid damage indicators

Take photos of the device. Documenting the condition before and during the teardown helps in reassembly and diagnostics.

Inspecting the seam between the frame and the display is critical, as this determines the method for separating components later.

Step 2: Removing the Back Cover

Most tablets use adhesives instead of screws. Gentle heat loosens the adhesive around the frame. A suction cup can lift a small section of the panel, allowing thin plastic tools to slide in.

Common risks here:

- Cracking plastic back covers

- Warping aluminum frames

- Chipping the paint finish

Slow prying with constant heat distribution is the safest method.

Step 3: Disconnecting Internal Shielding

Under the cover, you’ll find:

- EMI shields

- Access plates

- Plastic or metal internal housings

Removing these without bending or treating them harshly ensures that electromagnetic protection remains intact later. Some shields snap in, while others are soldered.

This step requires patience—rushed work damages clips and ridges that secure shielding in place.

Step 4: Detaching the Battery Assembly

Battery removal is one of the most challenging parts of the tablet teardown challenge. Manufacturers glue batteries firmly to prevent movement and reduce swelling risk.

Best practices:

- Apply low, consistent heat

- Avoid sharp tools

- Use isopropyl alcohol to weaken adhesive

Never puncture or bend lithium-ion batteries. Doing so can cause thermal runaway.

Step 5: Separating Display Components

Modern displays are laminated—meaning the LCD and digitizer act as a single unit. This drastically increases failure risk during separation.

Technicians must:

- Maintain the display temperature around 70–80°C

- Use multiple pry points

- Open slowly to avoid ribbon cable damage

Since the display is often the most expensive part of a tablet, extra caution is required.

Step 6: Motherboard Removal

The motherboard is the “brain” of the tablet. It contains:

- CPU

- RAM

- Storage

- Power management ICs

- Wireless chips

Every cable attached to the board must be documented. Each connection uses a delicate latch mechanism that can easily break.

Removing the motherboards from compact tablets requires navigating:

- Hidden screws

- Deep adhesive pockets

- Fragile cable routing

Step 7: Camera and Sensor Extraction

Cameras are connected using ultra-thin cables. Sensors include:

- Ambient light sensors

- Proximity modules

- IR blasters

- Accelerometers

These parts are easy to misplace. A magnetic tray is essential.

Step 8: Speaker and Antenna Module Removal

Speakers are glued and often enclosed in plastic chambers for acoustics. Antenna lines are delicate and follow specific routing patterns.

Removing them improperly can reduce signal quality when reassembled.

Step 9: Charging Port Teardown

Charging ports are typically:

- Soldered directly

- Part of sub-boards

- Held with multiple layers of adhesive

Tablets often require hot air rework stations for port removal.

Step 10: Logic Board Analysis

With boards removed, the tech can identify:

- Burn marks

- Corrosion

- Loose connectors

- ESD damage

- Shorted capacitors

Logic board inspections require magnification and precision.

Step 11: Frame and Structural Integrity Inspection

A teardown isn’t complete without analyzing the frame. Check for:

- Bends

- Cracks

- Adhesive residue

- Structural weak points

This helps determine repair viability and long-term reliability.

Step 12: Full Reassembly Overview

Reassembly should always be performed in reverse order, documenting each step. Using fresh adhesive is essential for structural integrity.

Real-World Challenges in Tablet Disassembly

Adhesive Problems and Heat Distribution

Inconsistent heat application is the primary cause of accidental damage.

Ribbon Cable Survivability

Ribbons can tear with minor pressure, making careful handling essential.

Professional Repair vs DIY Teardown

When to Call a Professional

If you’re unsure—go pro. Tablets are among the hardest consumer devices to repair.

Risks of DIY Tablet Disassembly

- Screen cracking

- Battery swelling

- Connector snapping

- Logic board damage

FAQs

1. Are all tablets difficult to disassemble?

Most modern tablets are difficult due to adhesives and compact construction.

2. Can I repair my own tablet?

Yes, but only if you understand the risks and have proper tools.

3. What is the most fragile part during a teardown?

The laminated display is the easiest part to crack.

4. Can a tablet teardown void warranty?

Yes, opening the device usually voids the warranty.

5. Why do manufacturers make tablets hard to repair?

Mostly for thinness, durability, and protecting components.

6. Where can I learn more about tablet teardowns?

A reliable resource Website: https://SydneyCBD.repair/locate-us

Conclusion

Completing the tablet teardown challenge requires patience, skill, and the right tools. While many tablets seem “unfixable,” a careful and methodical approach reveals that repair is entirely possible with the correct technique.

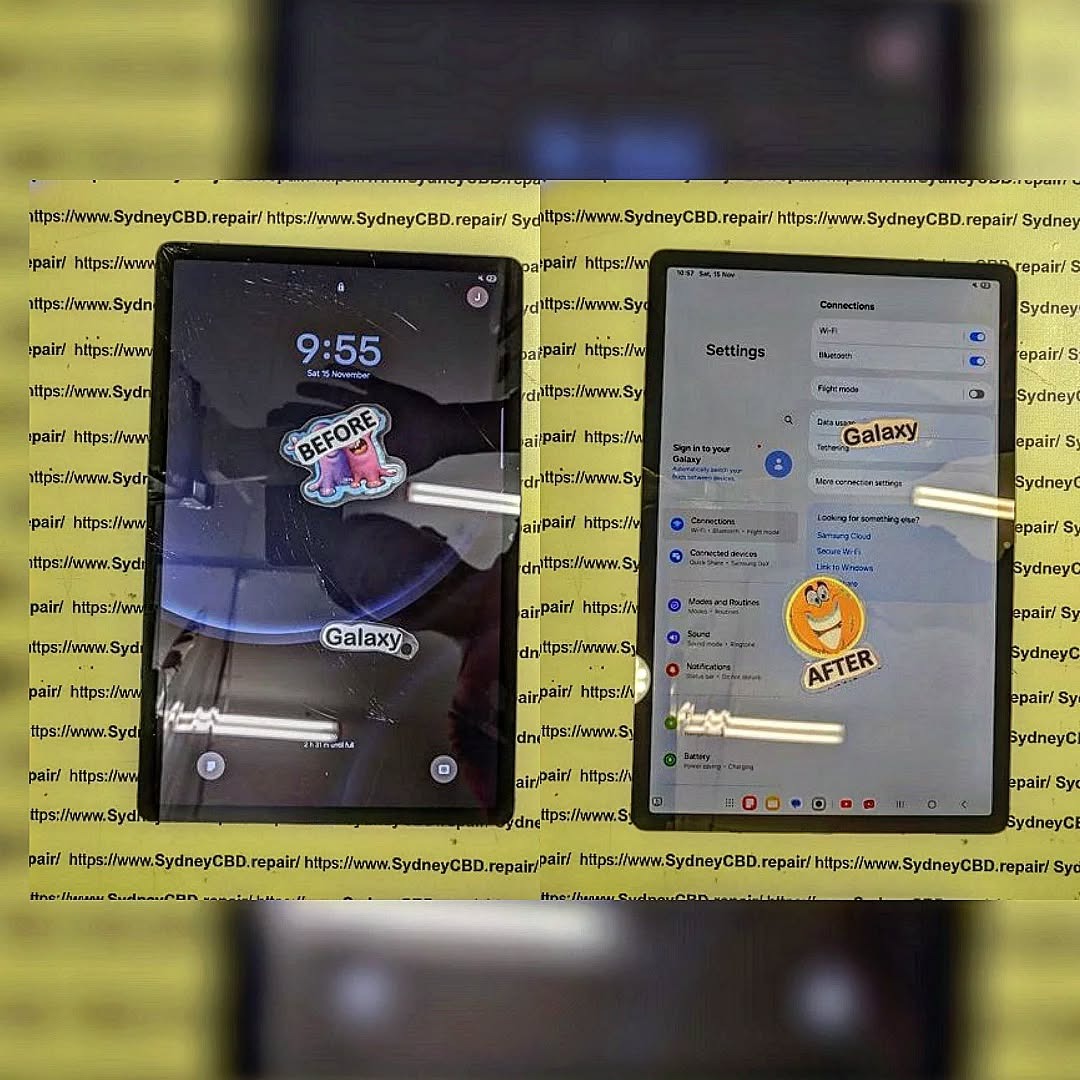

David from Sydney CBD Repair Centre – The Best place to fix mobile phones as 6 Years In A Row! Top Mobile Phone Repair In Sydney. More than 2000 Positive Reviews on Google and Same Day Repairs.

We take pride in delivering exceptional repair services for all major phone brands including Apple, Samsung, Google, and more. Our expert technicians use only genuine parts and offer 90days warranty on repairs. Located in the heart of Sydney CBD, we’re your one-stop solution for all mobile device repairs.

Our commitment to excellence has earned us the trust of thousands of satisfied customers. Whether it’s a cracked screen, battery replacement, or water damage repair, we handle it all with professional care and expertise. Walk in today and experience why we’re Sydney’s #1 choice for mobile phone repairs.

Visit us for:

✓ Same Day Express Repairs

✓ Genuine Parts Guarantee

✓ Professional Technicians

✓ Competitive Pricing

✓ 2000+ 5-Star Google Reviews

✓ 6-Time Award Winner for Best Phone Repairs

Sydney CBD Repair Centre – Where Quality Meets Reliability.

Call : +61280114119

Website: https://SydneyCBD.repair/locate-us